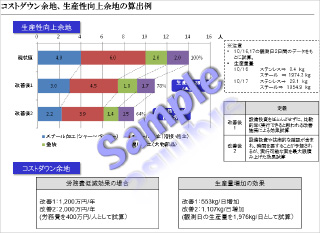

There are various targets for cost reduction. Therefore, we will pursue the lowest ultimate cost by promoting an appropriate cost reduction program according to the aim of cost reduction and the target cost.

In the case of labor costs, we aim to realize the lowest ultimate labor costs by making full use of programs such as labor productivity improvement, equipment productivity improvement, and production design based on IE (Industrial Engineering) at the factory.

In the case of externally purchased items such as raw materials and indirect materials, we aim to realize the lowest ultimate cost of externally purchased products by applying the program from both the unit price and the usage amount, such as the procurement cost reduction program from the viewpoint of unit price reduction and the yield improvement program from the viewpoint of usage amount reduction.

Also, regarding equipment procurement and construction procurement, we will apply a program that combines procurement cost reduction and execution budget management level up.

In the case of logistics costs, we will apply a program to reconstruct the logistics process, such as implementing 3PL and reviewing logistics bases, in addition to reducing logistics costs such as transportation and delivery costs and cargo handling costs.

For factory indirect labor costs and sales costs, we aim to achieve lowest ultimate costs by applying programs that streamline operation

A new factory project is a great opportunity to reform the way of manufacturing itself.

In order to avoid mere reconstruction, JMAC believes that a consistent reform concept which means to draw up the desired goal at the early stages of consideration is important.

Starting from the production system reform concept、how can we achieve our goal by utilizing advanced technology for buildings/ facility and information systems.

As well as strengthening factory management such as daily improvement control and organization/human resources management which the overall design is the key to success.

| Customer needs | JMAC Value Provided (Program) |

|---|

| Current needs | Want to achieve SDGs/energy saving goals | Sustainability Transformation x New factory design support |

|---|---|---|

| Want to add smart factory elements | Smart factory design support by using image cells | |

| Want to move forward with automation | Concept-design-implementation automation support | |

| Want to take another look at production base and production strategy | Formulate production strategy |

| Needs for universal production system reform | Want to fundamentally review production system | Ideal QCDF design approach |

|---|---|---|

| Want to incorporate innovative elements | Open innovation promotion support | |

| Want to improve productivity by extending existing lines | Loss visualization・reduction plan formulation by using IE as a starting point | |

| Want to be evaluated for design content | New factory design assessment service |

| Project needs specific to new factories | Want to choose the optimum vendor | Support services for creating and selecting RFPs by vendor |

|---|---|---|

| Want to select a general contractor through competitive bidding | Competitive bidding service in collaboration with design offices | |

| Want someone to tell should start from where | Project management administrative office support service | |

| Insufficient promotional resources | Functional agency support service (vendor control, etc.) |

| Field | Theme | Client |

|---|---|---|

| New factory construction | Realization of a new integrated manufacturing plant that integrates development, manufacturing, and logistics | Chemical |

| New factory construction | Smart factory concept planning | Transport equipment |

| Factory relocation | Relocation due to aging(New production system with labor saving target of 50%) | Food |

| Factory consolidation | Construction of next-generation factories to realize medium- to long-term production strategies | Machine tools |

| Renewal of factory equipment: abolish or merge | Manufacturing base reform: Renewal and relocation of new factory equipment | Food・agriculture |

| New factory construction: consolidation | Consolidation of manufacturing bases and construction of new factories to ensure survival | Mechanical equipment |

How much room is there for cost reduction?

What is the productivity level of own factory compared to other companies?

Do you feel that there are more equipment failures and defects than other companies?

Don't know what to do for the often changes of production plans and having many inventories?

Do you feel that the vitality of employees is not accompanied?

Is the executive working well?

| Field | Theme overview | Client |

|

Production system

Factory profit innovationProductivity improvement Quality improvement Procurement / Purchasing etc |

Support for policy management system construction and improvement implementation | "Optical product manufacturing (Japanese company)" |

| Headquarters / Factory Cost reduction | Non-ferrous metal (Japanese company) | |

| Support for improving production quality | White goods manufacturing (Japanese company) | |

| Equipment maintenance system construction and implementation support | Siam Cement Group (Thai company) |